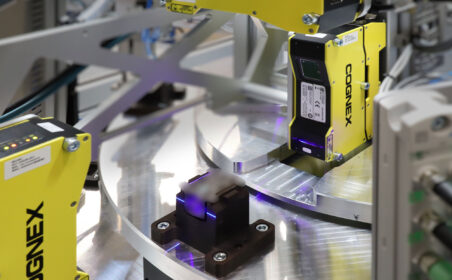

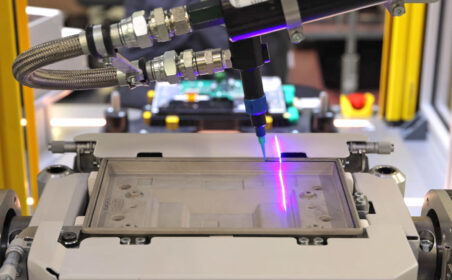

Assembly & Test System with Rotary Indexing Tables

Aumotive safety equipment is an area that must meet highest quality standards at all times. Hoob delivered automated assembly and testing system to one of world`s top automotive players producing safety components to passenger cars.

Challenge

High volume production for automotive safety product.

- Short cycle times

- High production volumes

- Automated feeding

- Dimensional measurement of the product in takt with assembly

- Pressure testing

- Induction welding

- Keeping assembly and testing within takt time limits.

- Cooling of the product.

Solution

Automated assembly & test system based on two Rotary Index Machines.

- Assembly Cell

- Automated component feeding with vibratory bowls and linear feeders

- 8-position indexing table for assembly positions

- Induction welding station

- Test Cell

- Pressure testing

- Dimensional checks using 3D scanning

- Sorting of PASS and FAIL components